Prototype Development

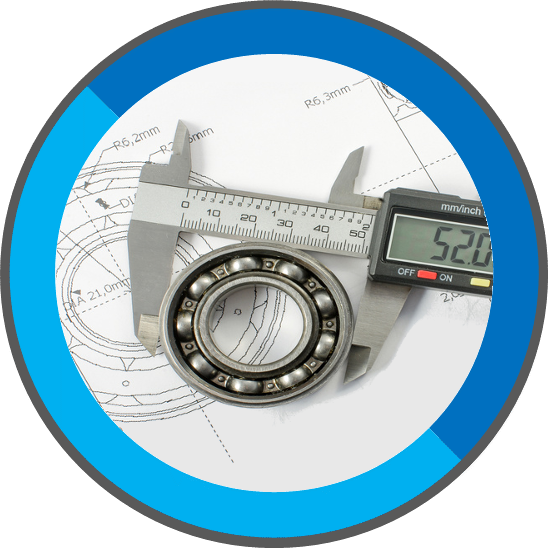

The term ‘Rapid Prototyping’ is used is to describe the process that follows on from the initial design stage. Rapid protoytyping is a system of developing three dimensional stereolithographic designs for a number of applications and purposes. A virtual design is taken from the computer, and then is converted intoa physical three dimensional model of the prototype. The finished article will correspond identically to the original computer model: this is know as a WYSIWYG (What You See Is What You Get) process. Data is transferred from CAD models and subsequently, the model can be layered up accordingly and thus the final model is created by a three dimensional printer.

For Solid Freeform Fabrications, multiple materials are used in the construction of the prototypes; the reason for this is that in order to create ‘negative volumes’, such as voids within models, a material with a low melting point has to be used.

The main material of construction has a high melting point and thus once the main model is constructed, it can then be heated to melt the internal materials to produce the voids and negative volumes.

Our rapid prototyping techniques have the advantage of being able to create objects and elements for our clients in a single step process with high repeatablility, both cost effectively and carbon neutrally.